AdvancedSeal - Integral Sealer

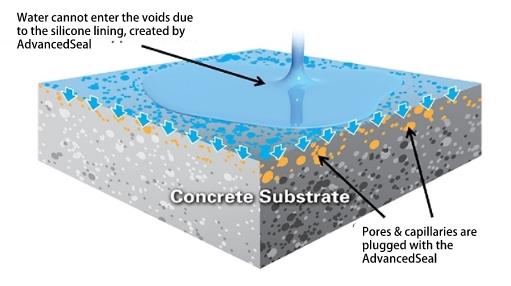

AdvancedSeal is an integral concrete sealer that drastically reduces water penetration, increases long-term durability, improves color vibrancy, and starts protecting from day one. Rather than sealing weeks after installation, Advanced Seal protects like a topically sealed pavement from the day it is poured.

We recommend AdvancedSeal in ALL exterior flatwork mixes.

Benefits of AdvancedSeal

- Provides protection through the full depth of concrete

- No applying or additional work for contractors

- Sealer prevents water ingress in slab

- Enhanced cosmetic look

- Reduces water penetration and increases long-term durability

Curing & Sealing

Whether using Advanced Seal or not, all concrete installations should be cured. Curing applications should begin immediately after the last finishing procedure. When using AdvancedSeal l it is especially critical that water based curing compounds be applied at that time. Shortly after final set the AdvancedSeal's chemical reaction that produces the concretes water repellency begins to form. At that point the concrete becomes hydrophobic, which will cause water to bead on the surface.

Other benefits to installing a curing, curing & sealing compound, or penetrating sealer:

- Keep the surface of the concrete from drying out due to evaporation caused by low humidity, wind or both

- Create an additional membrane to help keep deicing chemicals from coming into direct contact with the concrete surface.

- Improved stain resistance

- Improved appearance

AdvancedSeal will provide a life long barrier against water intrusion, however in our harsh winter climate we recommend a "belt & suspenders" approach of maintaining a topical film forming or penetrating sealer every 2-3 years.

We offer a full line of curing compounds, sealers, and other chemicals needed to complete a concrete installation.

Caring For Your Concrete

Contractors

- Avoid adding or spraying water on the surface to enhance finishing

- Avoid premature finishing, allow bleed water to evaporate from the surface prior to continuing the finishing process. Working the bleed water back into the surface increases the water cementitious ratio at the surface weakening it—which will lead to scaling

- Avoid overworking the surface as it can significantly reduce or destroy the air entrapment at the surface, making it susceptible to scaling in freezing conditions

Homeowners

- Do not use any deicing chemicals or salts. Use sand or other grit materials for traction

- Direct water off of slabs year round

- Keep snow cleared off of concrete wherever possible

- Concrete should be cleaned at least once per year in the spring, ideally in May to remove any dirt, salt and grime build up. This is the optimal time to reseal the concrete as well.

- Reseal your concrete every 2 – 3 years depending on its wear. Sealing and periodic resealing of the concrete surface not only reduces moisture infiltration, but also helps reduce staining on the surface of the concrete.

- Remove spills from concrete as soon as possible using a concrete-safe cleaner. Spills can lead to difficult-to-remove stains, so we advise they be cleaned immediately.

- Keep plows from direct contact with the concrete surface. These can gouge, scratch, accelerate wear on your concrete, and leave unsightly rust stains

- Use high-grade concrete sealers. We only sell high quality commercial grade products.

- For concrete that is sinking or sloping back into structures, we recommend having the concrete lifted or replaced to ensure proper drainage and avoid any water damage to the surrounding structures.